Your ultimate digitalized solution for real-time data monitoring in manufacturing facilities. At RytNow, we are passionate about empowering manufacturing plants with cutting-edge IoT software and hardware, enabling seamless monitoring and optimization of production processes.

RIMM helps to Achieve optimal production efficiency and gain comprehensive operational insights by effortlessly tracking OEE, machine utilization, and downtime, without the need for manual data entry.

Seamlessly connect, gather, and visualize data from shop floor equipment for enhanced transparency and data-driven decision-making.

Efficiently monitor production performance with historical data, enabling in-depth analysis at different levels (shifts, cells, machines, operators), providing comprehensive insights and performance breakdowns.

Visualize, analyze, and optimize OEE by gaining actionable insights into cycle times, performance metrics, machine availability, and quality indicators. Monitor and enhance production efficiency with data-driven decisions.

Gather production data from equipment seamlessly, without operator inputs.

Streamline Downtime Capture for Enhanced Efficiency

Visualize machine utilization by hour, shift, day, week, and month to analyze trends

Gain instant insights with clean dashboards, clear machine status and analysis through color-coded tiles.

Safely handle and access your data from any location using our smooth cloud computing solution.

Optimize resource consumption efficiently with our real-time energy monitoring system

Maintain optimal conditions with our real-time fluid temperature monitoring system.

Elevate efficiency with our RFID-enabled auto tool detection for smooth operations

Stay connected and empowered on the go with our manufacturing mobile app.

Gain immediate visibility into production metrics with our instant performance reports.

Digitize documentation for enhanced accessibility and efficiency with our e-docs on the shop floor.

Effortlessly connect and collaborate with external systems through seamless third-party integration.

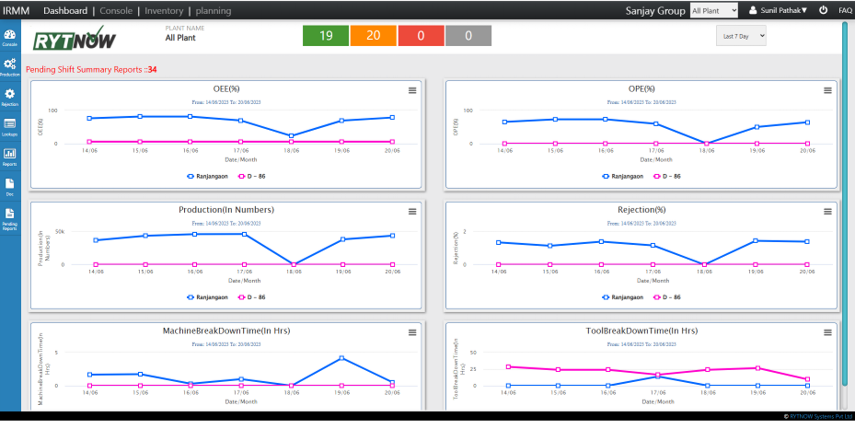

The main dashboard is accessible to Admin and Management, displaying crucial plant data through a trend chart (OEE, OPE, Production, etc.). It allows easy comparison of data from all plants, adjustable for the past 7 or 365 days.

RIMM offers a console view for the selected plant, with each box representing a machine color-coded to indicate its status. It provides a quick overview of all machines, production data, shots, rejections, process info, Energy, and temperature readings from the last 10 minutes of the current shift. Clicking on a box reveals more detailed information.

Designed for management, this system provides real-time data for each machine, ideal for shop floor display. It shows OEE with its components (Availability, Performance, and Quality) for the current shift, compares actual production to target production, identifies the assigned operator, and provides reasons for downtime.

Supervisors can update real-time status for all resources (Machine, Tool/Operation, Operator, Electricity, Raw material, etc.). A timeline view shows overall changes in the current shift, with color-coded representations of resource status and customizable data from previous shifts.

The production chart compares actual vs. target production hourly, with rejection numbers. It also displays energy consumption per hour (in kWh) and per part (in kWh) for the current shift and previous shifts (accessible through shift tabs).

RIMM offers diverse reports like Breakdown, Customer, and Performance. Accessible reports include machines, production, and tool analysis. Tabular and chart formats are available for easy presentation.